This is the blog for the Philadelphia University Industrial Design Fabrication class. The class focuses on mock-up and prototyping techniques used in Industrial design. Comments are welcome, we would love to hear what you think.

Wednesday, April 15, 2009

final proposal

for my final project i didn't know what to do but as i was playing with one of the halves of the egg mold i made i realized that it spins really well like a dadle or a top that i use to play when i was little so i decided why not make a top out of cement? haha i know its a bit of a strech but its so cool hah i would have to make the mold shape out of yellow foam on the laith and then cast the mold with smooth on after the mold is made i would then pour the morder into the mold and while it is curing i would insert some kind of rod i still don't know what for your hand to grasp so you could spin the top. but first i have to fix the problem with the morder that it is to britle so im going to try and add cement into the mix i have to play around with the ratio between cement and morder or also try cement compond and morder to see what makes it harder and less britle

Carolyn Final Proposal

Needed Materials

• Different colored glass

• Glass cutter

• Pliers to snap glass

• Soldering iron (120 watt)

• Solder 60, 40

• Copper foil

• Flux

After completely all my experiments I have decided I want to make a candle holder for my projects. I think a candle holder will allow the light of the candles to show the true beauty of the glass. I plan on making it a set of four candle holders. The holder will make a peek up in the center and peek down in the front of each section to allow you to see the different sections and colors of glass. I plan on using three different glass colors/patters; clear, white, and a clear/white/black swirl. The white would make the base, and the small detailing trianges. The swirl will trim the top. I have still not desided if I want to etch into the glass but the white effect of the etching would go well with the other colors. This design will allow me to use what I have learned about cutting glass and how you can cut our corners but not out from other areas. It will also have me solder pieces that are flat egde to egde, and make ninety degree corners.

experiments

for my final experiment i decided to to a few more the first one i tried was making a very thin mold to see the actual limits of the morder but also i incorporated a parttern into the mold

for my final experiment i decided to to a few more the first one i tried was making a very thin mold to see the actual limits of the morder but also i incorporated a parttern into the moldafter that i also did a very tiny mold out of a marble in plater first i made the plaster mold by putting a layer of clay in a container and inserting the marble half way in after that i poured the plaster into the container after the plaster set i removed the mold and poured the concrete into the tiny mold. i also decided to cheat a little bit and made a 2 part mold with an ester egg haha so i just put in the cement into the 2 halves and let them dry to glue them later but as the cement was cured i drooped one of the halves and it sort of cracked because it was very britle but the other half wasn't, so i could not glue the 2 parts together. another thing that i did was to try and paint the cement so i did 2 pieces one with just the spray paint and one with primer and then spray paint i saw that it was a better result with the primer first and it got a very good pigment to it, i also tried to paint the cement with acrylic but it didn't look as good as i wanted it to

Carolyn's 2nd Solder Attempt

After my first attempt of soldering the glass together it was decided that my soldering iron was not strong enough. I have since found out the the soldering iron needs to be at least 80 watts. Lucky I was able to barrow a 120 watt soldering iron from Rocky. I have since tried to solder using the more powerful iron and it works much better and turns the solder to an almost complete liquid state allowing it to spread much easier and create a smooth line. Now that I have achieved I smoother line I am much more confindent in using this method to join the pieces of glass together. In doing these experiments I have used up all my solder. I went to Stanleys and tried to buy new solder but but they do not carry the type of solder I need because it has lead in it and PA laws make it hard to aquire in this state. For this reason I have had to order the solder and get it sent to me, putting my project on hold unfurtunity for a few days.

Final Project: Plaster

From my experiments I learned that plaster is good for molding, painting, and securely holding objects. The design for this project actually came from a previous ideation of mine last year. It is an ashtray which takes its form from the classic chalk outlines of bodies at crime scenes. Lung shaped vessels are recessed into the form, where the ash would go. I will make an illustrator file of the outline of the figure, print it out and mount it on a sheet of mdf or plywood. Then cut the form out and route the edges of one side to finish the mold to vaccuum form in styrene. After forming the recesses and gluing them into the mold Ill pour plaster to create the piece. Once the plaster has cured I need to remove it from the mold and begin applying primer and paint. The body form will be white and the vessels will be either red, black, or white. Below is a quick rendering of the design.

Change In Direction

Brice,

I came across some information today which informed me about the negative impacts of PVC on the environment. I had no idea of this when I picked the project and was was unaware while experimenting with the material. I came across an online resource that sums up the impacts like this. "This commonplace plastic is one of the most toxic substances saturating our planet and its inhabitants. PVC contaminates humans and the environment throughout its lifecycle: during its production, use, and disposal. Few consumers realize that PVC is the single most environmentally damaging of all plastics." Given this, I would like your permission to switch my material for the project. I realize that I would be about two weeks behind with experiments, but I am willing to work really hard to catch up in the next few days. My new material of choice is felt. Felt is a no-woven cloth that is produced by matting, condensing and pressing fibers. Some types of felt are very soft, others are tough to form construction materials. I would like to work with the soft felt material. I would like to experiment with its absorbing properties of water, its ability to mold around complex forms and curves and keep its shape after drying,its ability to mix with other, natural materials, and applying and mixing different dyes to create color. I would conduct and post all of my experiments this weekend. Bring them to class and develop a final product idea on Monday. I would greatly appreciate your feedback on this one. Thanks.

Sam

I came across some information today which informed me about the negative impacts of PVC on the environment. I had no idea of this when I picked the project and was was unaware while experimenting with the material. I came across an online resource that sums up the impacts like this. "This commonplace plastic is one of the most toxic substances saturating our planet and its inhabitants. PVC contaminates humans and the environment throughout its lifecycle: during its production, use, and disposal. Few consumers realize that PVC is the single most environmentally damaging of all plastics." Given this, I would like your permission to switch my material for the project. I realize that I would be about two weeks behind with experiments, but I am willing to work really hard to catch up in the next few days. My new material of choice is felt. Felt is a no-woven cloth that is produced by matting, condensing and pressing fibers. Some types of felt are very soft, others are tough to form construction materials. I would like to work with the soft felt material. I would like to experiment with its absorbing properties of water, its ability to mold around complex forms and curves and keep its shape after drying,its ability to mix with other, natural materials, and applying and mixing different dyes to create color. I would conduct and post all of my experiments this weekend. Bring them to class and develop a final product idea on Monday. I would greatly appreciate your feedback on this one. Thanks.

Sam

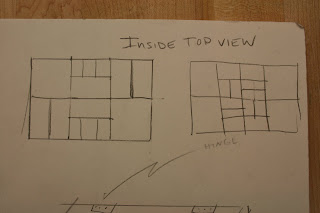

Copper Final Project: Eliot Coven

So I plan on making a jewelry box for my final project. The box will be a rectangular frame made of copper tubing using 90 degree elbow connector on the corners. There will be 2 separate rectangles, one on the top and one on the bottom. I will connect the top and bottom with T connectors. This is all 1/2 ID pipe and connectors. The top will be made out of copper sheet attached by hinges. If I have time I want to hammer a bevelled edge around the copper. If not I will make a lid and then attach a separate etched piece onto it using small nuts and bolts (to keep with the industrial feel of the whole piece) *as seen in the picture. I will then make the inside of the jewelry box with clear acyclic. I will make several compartments on the inside of the box to hold rings, necklaces, etc. In the other picture I have posted I laid out different inside arrangements for the acrylic. I will cut these out on the laser cutter and then connect them with weld-on, epoxy or super glue. If I can I want to figure out how to make an interlocking system for the inside compartments so it is strong and doesn't need glue. I will then try and rivet the acrylic to the copper piping on the inside of the box to hold the separate pieces together.

Sean's Steel Final

So my ideas so far for working with steel are an armor piece, a bowl with handles/base, or a n abstract sculptural piece. I'm leaning towards the sculpture, mostly because I can use welding and grinding more effectively with that. Sheet steel and possibly tubing would be my only materials.

Final Object

For my final object I plan to rotomold a flask. I want to mold a thread from an existing water bottle so that the final vessel can be closed with a standard bottle cap. I also plan to laser etch an image onto my mdf positive mold so it shows up in the final piece.

Subscribe to:

Comments (Atom)