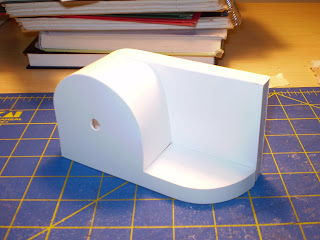

Here is my final model for the vacuum forming project. All the parts were done in 40 mm styrene. If I would have done something differently it would have been to use thinner gauge styrene for the connection lip, only because the radii were a little too tight for 40 mm.